- Fasteners

- Bolts and Screws, 140Ksi Ti

- Hex Head Bolts, 140Ksi Ti

- Metric M8-1.25

- Metric M10-1.25

- Metric M10-1.5

- Metric M12-1.5

- Metric M12-1.75 (Coarse thread)

- Metric M14-1.5

- Metric M16-1.5

- #10-32 (Fine thread)

- #12-24 (Coarse thread)

- SAE 1/4"-20 (Coarse thread)

- SAE 1/4"-28 (Fine thread)

- SAE 5/16"-18 (Coarse thread)

- SAE 5/16"-24 (Fine thread)

- SAE 3/8"-16 (Coarse thread)

- SAE 3/8"-24 (Fine thread)

- SAE 7/16"-14 (Coarse thread)

- SAE 7/16"-20 (Fine thread)

- SAE 1/2"-13 (Coarse thread)

- SAE 1/2"-20 (Fine thread)

- SAE 1/2"-20 (Fine thread) Reduced Head

- SAE 5/8"-11 (Coarse thread)

- SAE 5/8"-18 (Fine thread)

- SAE 3/4"-16 (Fine thread)

- Hex Flange Bolts, 140Ksi Ti

- Metric M6-1

- Metric M7-1.0

- Metric M8-1.25

- Metric M10-1.25

- Metric M10-1.5

- Metric M12-1.25

- Metric M12-1.5

- Metric M12-1.75

- Metric M14-1.5

- Metric M14-2.0

- SAE 1/4"-20 (Coarse thread)

- SAE 1/4"-28 (Fine thread)

- SAE 5/16"-18 (Coarse thread)

- SAE 5/16"-24 (Fine thread)

- SAE 3/8"-16 (Coarse thread)

- SAE 3/8"-24 (Fine thread)

- SAE 7/16"-14 (Coarse thread)

- SAE 7/16"-20 (Fine thread)

- SAE 1/2"-13 (Coarse thread)

- SAE 1/2"-20 (Fine thread)

- SAE 5/8"-11 (Course thread)

- SAE 5/8"-18 (Fine thread)

- SAE 3/4"-16 (Fine thread)

- Phillips Head Screws

- Torx Button Head Screws, 140Ksi Ti

- SAE #8-32 (Coarse Thread)

- Metric M3-0.5

- Metric M4-0.7

- Metric M6-1

- SAE #4-40 (Coarse Thread)

- SAE #4-40 (Fine Thread)

- SAE #6-32 (Coarse Thread)

- SAE #6-32 (Fine Thread)

- SAE #8-32 (Fine Thread)

- Metric M8-1.25

- Metric M10-1.5

- Metric M10-1.25

- SAE 1/4"-20 (Coarse thread)

- SAE 1/4"-28 (Fine thread)

- SAE 5/16"-18 (Coarse thread)

- SAE 5/16"-24 (Fine thread)

- SAE 3/8"-16 (Coarse thread)

- SAE 3/8"-24 (Fine thread)

- SAE 1/2"-20 (Fine thread)

- Torx Parallel Socket Head Screws

- Torx Countersunk Socket Screws, 140Ksi Ti

- Hex Flange Bolts Drilled for Safety Wire, 140Ksi Ti

- 12 Point Flange Bolts, 140Ksi Ti

- Parallel Socket Head Screws, 140Ksi Ti

- Metric M4-0.7

- Metric M6-1

- Metric M8-1.25

- Metric M10-1.5

- Metric M10-1.25

- Metric M12-1.75

- Metric M12-1.5

- Metric M12-1.25

- #8-32 (Coarse thread)

- #10-24 (Coarse thread)

- #10-32 (Fine thread)

- SAE 1/4"-20 (Coarse thread)

- SAE 1/4"-28 (Fine thread)

- SAE 5/16"-18 (Coarse thread)

- SAE 5/16"-24 (Fine thread)

- SAE 3/8"-24 (Fine thread)

- SAE 3/8"-16 (Coarse thread)

- SAE 7/16"-14 (Coarse thread)

- SAE 1/2"-13 (coarse thread)

- SAE 1/2"-20 (fine thread)

- Tapered Socket Head Screws, 140Ksi Ti

- Button Head Screws, 140Ksi Ti

- Countersunk Socket Screws, 140Ksi Ti

- Metric M12-1.25

- Metric M5-0.8

- Metric M6-1

- Metric M8-1.25

- Metric M10-1.25

- Metric M10-1.5

- Metric M12-1.5

- Metric, M12-1.75

- Metric M14-2

- Metric M16-1.5

- #8-32 (Fine thread)

- #10-24 (Coarse thread)

- #10-32 (Fine thread)

- SAE 1/4"-20 (Coarse thread)

- SAE 1/4"-28 (Fine thread)

- SAE 5/16"-18 (Coarse thread)

- SAE 5/16"-24 (Fine thread)

- SAE 3/8"-16 (Coarse thread)

- SAE 3/8"-24 (Fine thread)

- SAE 7/16"-14 (Coarse thread)

- SAE 7/16"-20 (Fine thread)

- SAE 1/2"-20 (Fine thread)

- Hex Head Bolts, 140Ksi Ti

- Washers, 140Ksi Ti, AN, & Stainless

- Nuts, 140Ksi Ti & Steel

- Titanium Hardware Kits

- Studs, 140Ksi Ti

- Bolts and Screws, 140Ksi Ti

- Sprint/Midget/Micro

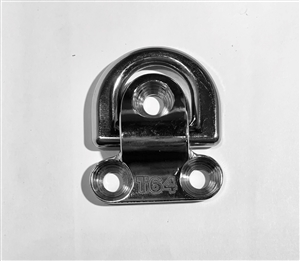

- Marine

- Drag Race

- Wheel Studs & Nuts

- IndyCar

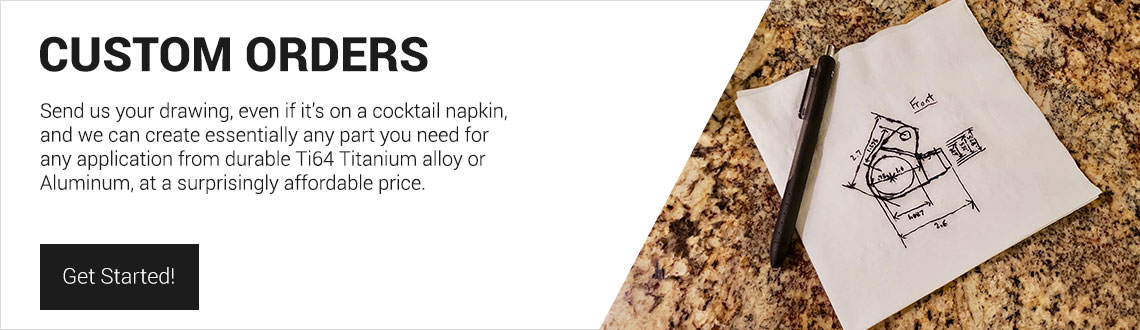

- Custom Fabrication

- Technical Info